Carbon fibre is a remarkable material that has revolutionised numerous industries. Also known as graphite fibre, this polymer is renowned for its light weight and strength, making it the perfect material for manufacturing parts for uses in space, motorsport, military and renewable industries (to name just a few).

Understanding carbon fibre

Carbon fibre is composed of thin and strong crystalline filaments of carbon that are tightly bonded together, resulting in a high-strength structure. The strength of carbon fibre is further enhanced when these filaments are twisted together. The carbon atoms within the fibres are arranged in a crystal alignment, forming a lattice-like structure. These fibres are incredibly fine, typically measuring around 5-10 micrometres in diameter, which is smaller than a human hair. Carbon fibre is made of pure carbon with minimal impurities, so it is considered a high-purity material. This pristine composition contributes to the exceptional performance characteristics of carbon fibre, making it a sought-after material in various industries.

The properties of carbon fibre

Carbon fibre possesses several notable properties that make it highly desirable for various applications. Here are some key properties of carbon fibre:

- High strength-to-weight ratio: Carbon fibre is exceptionally strong and lightweight. It has a higher tensile strength compared to materials like steel while being significantly lighter, making it an ideal choice for applications where weight reduction is crucial.

- Stiffness: Carbon fibre exhibits high stiffness or rigidity, which means it can resist deformation under applied loads. This property allows carbon fibre components to maintain shape and structural integrity even under significant stresses.

- Low density: Carbon fibre has a low density, resulting in lightweight structures. This characteristic is advantageous in industries such as aerospace and automotive, where reducing weight is critical to enhancing fuel efficiency and overall performance.

- Excellent fatigue resistance: Carbon fibre exhibits excellent fatigue resistance, meaning it can withstand repeated loading and unloading cycles without experiencing significant degradation in performance. This property makes it suitable for applications that involve cyclic loading or vibration, such as sporting equipment.

- Corrosion resistance: Carbon fibre is highly resistant to corrosion and does not rust or corrode like metals. This characteristic makes it advantageous in environments where exposure to moisture or chemicals is a concern.

- Electrical conductivity: Carbon fibre is electrically conductive, allowing it to dissipate electrical charges. This property is important in applications such as aerospace and automotive, where electrical grounding or electromagnetic shielding is necessary.

It’s worth noting that the specific properties of carbon fibre can vary depending on the manufacturing process, fibre orientation, resin system, and other factors used to produce the material. Different carbon fibre grades and configurations can be tailored to meet specific requirements for different applications.

How is carbon fibre manufactured?

Carbon fibre is manufactured through a multi-step process that converts a precursor material into the final product. A general overview of the carbon fibre manufacturing process is:

- Precursor Material Selection: The process begins with selecting a precursor material, which is typically a polymer-based fibre such as polyacrylonitrile (PAN), pitch, or rayon. PAN is the most commonly used precursor material due to its excellent carbonisation properties.

- Fibre Spinning: The selected precursor material is spun into long, thin fibres through a process called fibre spinning. This process involves dissolving the precursor material in a solvent, extruding it through fine nozzles, and solidifying the fibres by evaporating the solvent or through a chemical reaction.

- Stabilisation: The spun precursor fibres undergo a stabilisation process to convert them into a thermoset material that can withstand high temperatures without melting. Stabilisation involves heating the fibres in an oxygen-free environment, typically between 200°C and 300°C. This step chemically modifies the fibre structure and removes non-carbon atoms, leaving a more carbon-rich material behind.

- Carbonisation: After stabilisation, the fibres are subjected to a high-temperature carbonisation process. The stabilised fibres are heated to extremely high temperatures, often above 1,000°C, in an inert atmosphere with a limited oxygen supply. This high-temperature treatment causes further removal of non-carbon elements, resulting in a material that is predominantly composed of carbon atoms.

- Finishing Treatments: Once carbonised, the fibres may undergo additional treatments to enhance their properties or modify their surface characteristics. These treatments may include surface coatings, sizing application, or application of finishes to improve bonding with resin matrices or other composite materials.

It’s important to note that the manufacturing process can vary and often, as we will learn below, pure carbon fibre is not used; instead carbon fibre is used in the creation of a composite material.

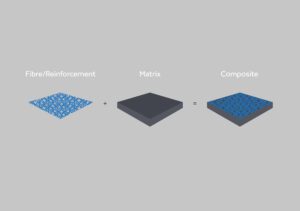

Carbon fibre in composites

Pure carbon fibre is not often commonly used. Alone it is a brittle and delicate material, so using it in its pure form without any matrix would result in a structure that lacks the necessary strength and integrity for practical applications. Instead, it is commonly combined with a matrix material and acts as reinforcement in the production of composite materials.

When incorporated into composites, carbon fibre enhances the strength, stiffness, and durability of the resulting material. It offers a high strength-to-weight ratio, creating composites that are lightweight yet strong, which makes them suitable for applications where weight reduction is crucial. Carbon fibre’s stiffness allows composites to maintain their shape and resist deformation under applied loads. Additionally, carbon fibre composites exhibit excellent fatigue resistance and corrosion resistance, making them suitable for demanding environments. Quality composite manufacturing utilises of cutting-edge machinery, advanced tooling, and precision equipment.

When incorporated into composites, carbon fibre enhances the strength, stiffness, and durability of the resulting material. It offers a high strength-to-weight ratio, creating composites that are lightweight yet strong, which makes them suitable for applications where weight reduction is crucial. Carbon fibre’s stiffness allows composites to maintain their shape and resist deformation under applied loads. Additionally, carbon fibre composites exhibit excellent fatigue resistance and corrosion resistance, making them suitable for demanding environments. Quality composite manufacturing utilises of cutting-edge machinery, advanced tooling, and precision equipment.

Applications of carbon fibre

Carbon fibre, as a composite material, has a huge range of uses in a breadth of industries. Just a few examples include:

- In the aerospace and space sectors, carbon fibre is extensively used in aircraft components, including wings and structural elements, as it provides excellent strength and weight savings.

- The automotive industry utilises carbon fibre in high-performance vehicles to enhance fuel efficiency and improve structural integrity.

- Carbon fibre is one of the leading materials used in the marine industry, with uses in superyachts, rescue vessels and more.

- Sports and leisure equipment, such as bicycles, tennis rackets, and golf clubs, benefit from carbon fibre’s lightness, strength, and stiffness.

- In the field of renewable energy, carbon fibre is employed in wind turbine blades to optimise performance.

- Carbon fibre has applications in advanced prosthetics within the medical industry

- It can also be used in the military and defence sector, creating bulletproof parts amongst a myriad of other uses.

Challenges and future developments of carbon fibre

While carbon fibre offers remarkable properties, there are challenges and ongoing developments in its use.

Some challenges for consideration include:

- The high cost of production limits widespread adoption.

- Recycling carbon fibre composites is difficult and expensive.

- Sustainability concerns regarding waste management.

Future developments aim to delve into:

- Research on cost-effective production methods and alternative precursor materials.

- Advancements in recycling technologies to improve sustainability.

- Integration of carbon nanotubes and graphene to enhance properties.

- Optimisation of carbon fibre structures for improved performance.

- Exploration of novel applications in renewable energy, electric vehicles, and space exploration.

These ongoing developments hold the promise of expanding the utilisation of carbon fibre and pushing the boundaries of its capabilities in the future. Read more on how Piran Composites are researching and developing to create the future of carbon fibre.

Concluding thoughts – what is carbon fibre?

Carbon fibre is an exceptional material that has revolutionised various industries due to its remarkable properties. Its high strength-to-weight ratio, stiffness, low density, excellent fatigue resistance, corrosion resistance, and electrical conductivity make it highly desirable for numerous applications. While the manufacturing process and use of carbon fibre in composites are crucial, the material’s potential is further enhanced by ongoing developments. Challenges such as high production costs and recycling difficulties are being addressed through research and advancements in technology. As carbon fibre continues to evolve, it holds great promise for expanding its utilisation in fields like renewable energy, electric vehicles, and space exploration, pushing the boundaries of its capabilities in the future.

Need help with carbon fibre composite part manufacturing?

Need help with carbon fibre composite part manufacturing?

Discover if composite materials and parts could help your business grow and develop. Speak to a composites expert today.

Carbon Fibre FAQs

Is there a difference between carbon fibre and carbon fiber?

No, there is no inherent difference between “carbon fibre” and “carbon fiber.” The difference lies in the spelling convention used in different regions. “Carbon fibre” is the British English spelling, while “carbon fiber” is the American English spelling.

Is carbon fibre expensive?

Carbon fibre is generally considered an expensive material due to its complex production process and the cost of precursor materials. However, its durability, lightweight nature, and long-term performance can make it cost-effective in the long run, as it reduces fuel consumption, extends component lifespan, and offers potential maintenance and operational cost savings.

Can carbon fibre be recycled?

Yes, carbon fibre can be recycled, but the process is currently challenging and not as widespread as traditional recycling methods for materials like plastics or metals. Carbon fibre composites are made up of a combination of carbon fibres and a resin matrix, which makes the recycling process more complex.

There are a few methods being explored for carbon fibre recycling:

- Mechanical Recycling: This method involves breaking down the composite structure mechanically, either through shredding or grinding, to recover the carbon fibres. The recovered fibres can then be used to produce new carbon fibre products, but the mechanical process may degrade the properties of the fibres to some extent.

- Thermal Recycling: Thermal recycling, also known as pyrolysis, involves subjecting the carbon fibre composites to high temperatures in an oxygen-depleted environment. This process breaks down the resin matrix, leaving behind carbon fibres that can be reused.

- Chemical Recycling: Chemical recycling methods aim to dissolve or depolymerise the resin matrix without damaging the carbon fibres. This process typically involves using solvents or chemical treatments to separate the resin from the fibres, allowing for their separate reuse.

What is carbon fibre in simple words?

Carbon fibre is a strong and lightweight material made up of thin strands of carbon atoms. Often, these strands, called fibres, are combined with a polymer resin to create a composite structure.

Are there any safety considerations with carbon fibre?

While carbon fibre is generally safe to use, there are a few safety considerations to keep in mind:

- Inhalation of Carbon Fibre Dust: Carbon fibre dust, especially during cutting or sanding operations, can release small particles that may be harmful if inhaled. It is essential to work in well-ventilated areas or wear appropriate personal protective equipment, such as a dust mask, to prevent inhalation of the fibres.

- Skin and Eye Irritation: Direct contact with carbon fibre can cause skin and eye irritation, similar to other fibres. It is advisable to use gloves, protective clothing, and safety goggles when handling carbon fibre to minimise the risk of skin irritation or eye injury.

- Electrical Conductivity: Carbon fibre is electrically conductive, and care should be taken when working with carbon fibre near live electrical systems. Proper grounding techniques and insulation should be employed to avoid electrical hazards.

- Thermal Conductivity: Carbon fibre has high thermal conductivity, meaning it can transfer heat quickly. Precautions should be taken when working with carbon fibre in high-temperature environments to avoid the risk of burns or thermal injuries.

- Fire Hazards: Carbon fibre is flammable and can burn when exposed to high temperatures or flames. It is crucial to store and handle carbon fibre materials away from potential ignition sources and follow appropriate fire safety measures.

It is important to note that these safety considerations apply mainly to the handling and processing of raw carbon fibre materials. Once carbon fibre is properly incorporated into a composite structure, these risks are significantly reduced, and the safety considerations shift towards the specific handling and use of the composite product.

Is carbon fibre stronger than steel?

Yes, carbon fibre is generally stronger than steel when put with the correct matrix and comparing their strength-to-weight ratios. Carbon fibre has a significantly higher tensile strength (the resistance to being pulled apart) compared to steel, while also being much lighter in weight. This means that carbon fibre can withstand higher loads and stresses for its weight compared to steel. In fact, carbon fibre’s tensile strength can be up to 10 times higher than that of steel while being only about one-fourth the weight. This exceptional strength-to-weight ratio is one of the key reasons carbon fibre is highly valued in various industries, such as aerospace, automotive, and sporting goods, where lightweight materials with high strength are desired for improved performance and fuel efficiency.

Need help with carbon fibre composite part manufacturing?

Need help with carbon fibre composite part manufacturing?