Advanced composites are revolutionising the medical field with their unique properties. This post outlines the advantages, history and use of composites in medical applications. Plus, we will explore the future trends of composites in medical devices, using real-life examples from leaders in the industry. So, what are composites in medical applications?

Table of Contents

Overview of Advanced Composites in Medical Applications

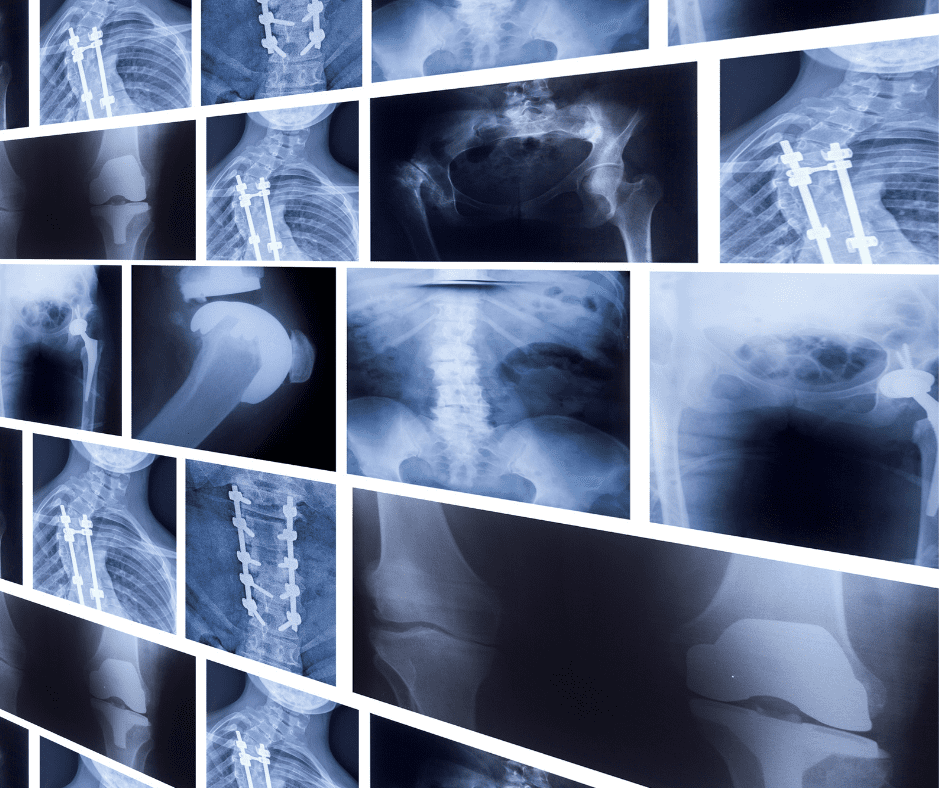

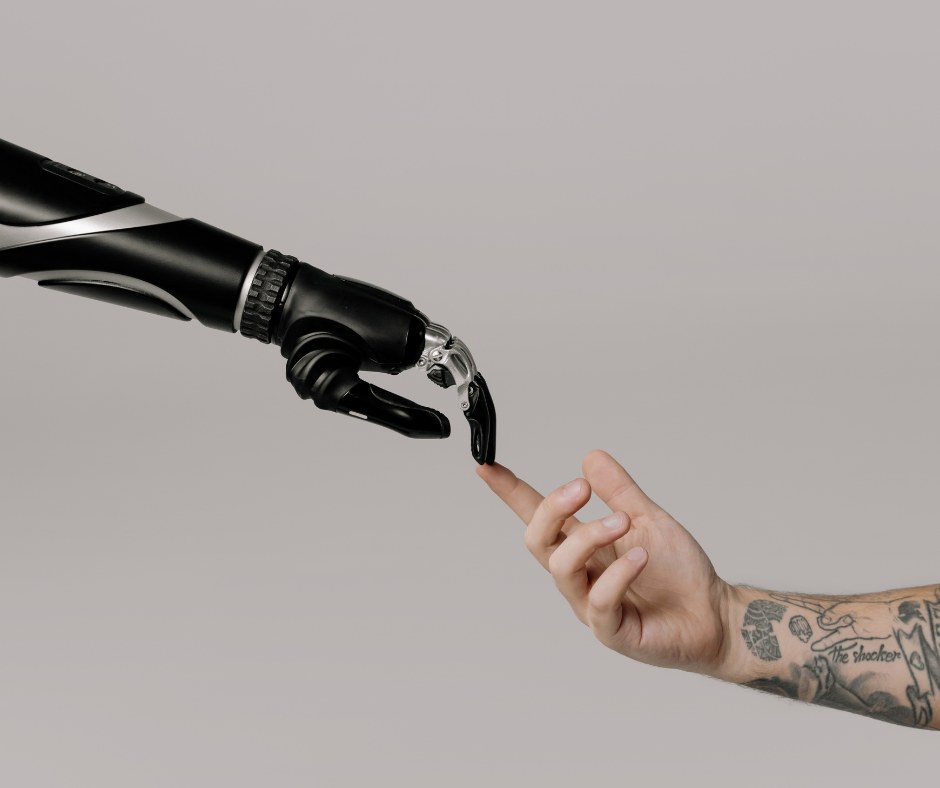

Advanced composites create lightweight, durable and biocompatible medical products. Composites such as carbon fibre, glass fibre and advanced polymers are used in prosthetics, surgical tools, hearing aids, dental implants, braces, health monitoring bands, endoscopic instruments, pin and plates, hip replacements, surgical robotics and exoskeletons to provide more efficient, patient-friendly healthcare solutions.

Characteristics and Advantages

The advantages of advanced composites in medical applications include:

- Strength-to-Weight Ratio – This reduces the overall weight of medical devices without compromising strength or functionality.

- High Corrosion Resistance – Composites can withstand sterilisation processes, which makes them ideal for repeated use in medical environments.

- Adaptable Design – This allows for customisations in design and functionality, such as when used in bespoke prosthetics.

- Biocompatible – Certain advanced composites are biocompatible (not harmful or toxic to living tissue) and can be used in medical applications, such as implants.

History and Evolution in Medical Use

Composites were first used in medical applications in the early 1970’s, and have been rapidly developed and used since then. Robert Mathys reportedly thought of the ‘cementless isoelastic hip stem’ in 1967, as an alternative to Sir John Charnley’s metallic hip implant. This isoelastic hip stem was a composite prosthesis made from a polyacetal copolymer, first implanted in 1973. Initially, the use of composites was limited due to cost and manufacturing complexities. However, as technology progressed, these materials became more feasible and composites began being used in prosthetics, surgical instruments and imaging equipment.

Advanced Composites in Prosthetics and Orthotics

Advanced composites can be used in a wide range of prosthetic limbs and orthotics such as splints, insoles, braces, spinal jackets and helmets. Other applications include knee and hip replacements, catheter tubing, surgical meshes, medical instruments, slow-release pill casings, implants and more. The innovative use of carbon fibre, glass fibre, and other composites has created more resilient, long-lasting, and effective aids, greatly enhancing the quality of life for users. This progress signifies a technical advancement and a leap towards more personalised and responsive healthcare solutions.

Design and Customisation Flexibility

Advanced composites offer an extraordinary level of design flexibility. These materials can be moulded and shaped to fit the unique contours of an individual’s body, ensuring a more precise and comfortable fit. This customisation extends to the aesthetic aspects as well, allowing for a range of finishes and colours that can match the wearer’s preferences, thereby enhancing the personal and emotional comfort of the device.

Use of Composites in Surgical Equipment

The evolution of composites in surgical equipment is driven by the need for tools that can withstand the rigours of complex medical procedures while ensuring patient safety and surgical efficiency. Advanced composites are used in surgical equipment such as surgical retractors and spreaders, endoscopic instruments, orthopaedic implants (pins and plates), dental drills and braces. They are also used in surgical robotics components to enhance precision in robot-assisted surgeries.

Precision and Durability in Surgical Instruments

Advanced composites contribute significantly to the precision and durability of surgical instruments. Their high strength-to-weight ratio allows for the creation of tools that are both lightweight and robust, reducing fatigue for surgeons during lengthy procedures. This level of precision is crucial in delicate surgeries, where exact movements and stability are paramount. Additionally, the durability of composite materials ensures that these instruments can endure repeated sterilisation and rigorous use, maintaining their integrity and performance over time.

Innovations in Minimally Invasive Surgery Tools

The field of minimally invasive surgery has particularly benefited from innovations in composite materials. These advancements have led to the development of tools that are not only smaller and more manoeuvrable but also more effective in performing complex procedures through smaller incisions. This minimally invasive approach, facilitated by composite technology, results in reduced recovery times and less postoperative discomfort for patients; a significant step forward in surgical care and patient outcomes.

Composites in Dental Applications

Composite materials have become integral in various dental procedures, enhancing both the functionality and aesthetics of dental work. They are used in composite resin fillings, dental crowns and bridges, braces, dental veneers and dental bonding agents. The combination of strength, aesthetic qualities, and biocompatibility allows for more effective and long-lasting dental solutions, revolutionising the approach to oral health care.

Advancements in Dental Implants and Orthodontics

The advancement of composites has improved various processes such as osseointegration in dental implants; in which the implant integrates with the jawbone, as a long-term solution for tooth replacement. In orthodontics, composites have enabled the development of less noticeable, more comfortable braces and aligners, greatly improving the patient experience. Also, instruments made from composites such as Carbon Fibre Reinforced Plastics (CFRP) work well alongside X-ray machinery, in which metal materials would interfere.

Biocompatibility and Aesthetic Benefits

The biocompatibility of advanced composites is a major benefit, as it minimises the risk of allergic reactions and the body rejecting implants. Aesthetically, these materials can be matched to the natural colour of teeth, providing a seamless and natural appearance in dental restorations. This combination of biocompatibility and aesthetic appeal significantly enhances patient satisfaction and outcomes in dental treatments.

Emerging Trends in Composite Medical Devices

Composites are now being used to create enhanced prosthetics with functional and biomechanical properties, such as the ability to feel temperature and touch. This was researched at the Johns Hopkins Applied Physics Laboratory (APL), in which temperature sensors were embedded into advanced prosthetics. This resulted in volunteers being able to feel cold drink cans for the first time since experiencing upper limb amputations. Other future trends may include composites playing a role in tissue engineering and regenerative therapies.

Wearable Medical Technologies

Wearable medical devices range from advanced biosensors to drug delivery systems and are becoming increasingly sophisticated, thanks to the flexibility and lightweight nature of composite materials. They offer continuous health monitoring and management capabilities, providing vital data and insights for both patients and healthcare providers. Examples include advanced hearing aids, fitness trackers, health monitoring bands and exoskeletons used for rehabilitation.

Future Directions and Research Opportunities

The future of composite medical devices holds immense potential, exploring regenerative medicine and personalised medical devices. The development of composites such as Nobio’s antimicrobial restorative materials is on the rise, which exsert particles with strong, concentrated electrostatic stress to kill bacteria and viruses in dental applications. Also, high-performance polymers such as Magnolia Trinity PEEK (which was first made available for the manufacture of medical devices in October 2023), combine carbon fibre, hydroxyapatite, and polyether ether ketone. This powerful combination of materials provides structural support, promotes bone growth, and resists wear and tear in joint replacements and prosthetic devices.

Challenges and Considerations of Composite in Medical Applications

The use of composites in medical applications, while advantageous, also presents several challenges and considerations. These issues need careful attention to ensure the safety, effectiveness, and feasibility of composite-based medical devices.

Regulatory and Safety Concerns

One area of concern is regulatory and safety aspects. Medical devices using composites must adhere to stringent regulatory standards to ensure they are safe to use. This involves rigorous testing for biocompatibility, stability, and potential toxicity. The complexity of composite materials can make this process challenging, as it’s crucial to understand how they interact with the human body over a period of time.

Balancing Cost and Performance

Another consideration is balancing cost and performance. While composites offer superior qualities, they can be more expensive than traditional materials. Therefore, the cost-benefit ratio must be considered, especially in healthcare settings where budget constraints are a reality. The challenge lies in developing composite materials and manufacturing processes that maintain high performance without escalating costs prohibitively.

Composites in Manufacturing Medical Devices

We cannot wait to watch the future of composites in medical devices unfold; combining advanced composites with innovative technologies creates an elixir of opportunities in the medical world. But now, it’s over to you.

Which advancements in composites in medical devices are you looking forward to witnessing in the future? Comment below to let us know your thoughts!

Did you know that here at Piran Composites, we excel in producing composites for X-Ray, CT and MRI machines, as well as prosthetics and robotic surgery tools? We are committed to innovation and investment in research and development, and we are excited to work with clients who share our passion for innovation in the medical world, as well as other sectors.

If you would like to find out more or have any questions, please get in touch with our friendly experts who are more than happy to find solutions for your medical application needs.