Composite Engineering & Tooling Solutions

Piran Composites specialises in designing and engineering high-quality composite tooling, including autoclave-cured composites, epoxy blocks, metallics, and carbon fibre.

Choose a team of composite engineering & design experts

Piran Composites is a leading provider of high-quality composite tooling solutions. Our expert team specialises in the design and engineering of tooling made from a variety of materials, including autoclave-cured composites, direct-machined epoxy tooling blocks, metallics, and thermoplastic carbon fibre. Our extensive experience allows us to create tooling that meets the specific needs of our clients, ensuring optimal performance and efficiency.

In addition to our tooling capabilities, we also design and engineer jigs and fixtures for a range of applications, including trimming, secondary bonding, and indexing. Our jigs and fixtures are custom-designed to meet the unique requirements of each project, ensuring precision and accuracy in every application.

What is composite engineering & design?

Design and engineering encompass the core disciplines that drive the creation and development of composite solutions. At Piran Advanced Composites, we specialise in these critical aspects of the manufacturing process. Design involves translating concepts and ideas into practical and functional solutions, ensuring that they meet the desired requirements and can be efficiently manufactured.

Engineering focuses on the technical aspects of turning designs into reality, incorporating structural integrity, performance optimisation, and manufacturability. With our expertise in design and engineering, we bring together innovative thinking, advanced techniques, and deep industry knowledge to deliver exceptional composite solutions that are lightweight, strong, and precisely tailored to our client’s needs.

What do Piran Composites offer

Let’s discuss your global business needs

Why choose Piran for design &

engineering?

At Piran Composites, we are committed to delivering the highest-quality solutions to our clients. Our expert team utilises the latest software and tools to create innovative and effective solutions that meet the rigorous demands of your industry. We handle all aspects of the design and engineering process in-house. This means seamless coordination, streamlined communication, and efficient project execution from start to finish.

Our team boasts years of combined experience in the industry, bringing a wealth of knowledge and expertise to every project we undertake which is reflected in our proven track record of successful outcomes and satisfied clients. We are established as a trusted and reliable partner in the field. When you choose Piran, you can be confident that you are working with a dedicated team that is committed to delivering high-quality results, leveraging our deep industry experience and ensuring your project’s success.

The process

Explore the design & engineering process within Piran Composites

World class facilities delivering guaranteed quality

Piran Advanced Composites stands out in design and engineering thanks to our state-of-the-art facilities. We firmly believe in investing in cutting-edge equipment, which enables us to deliver top-notch design and engineering solutions. We consistently evaluate and acquire tools and technologies that enhance our capabilities, ensuring that we stay at the forefront of the industry.

With a strong commitment to continuous improvement, we make constant and flexible investments to expand our current capabilities and embrace future technologies. By leveraging our advanced facilities, we are equipped to handle complex projects, push the boundaries of innovation, and provide our clients with exceptional design and engineering services that surpass their expectations.

Design & engineering market sectors

Explore the market sectors in which Piran Composites display their design & engineering capabilities

Aerospace

Space

UAVs

Military & Defence

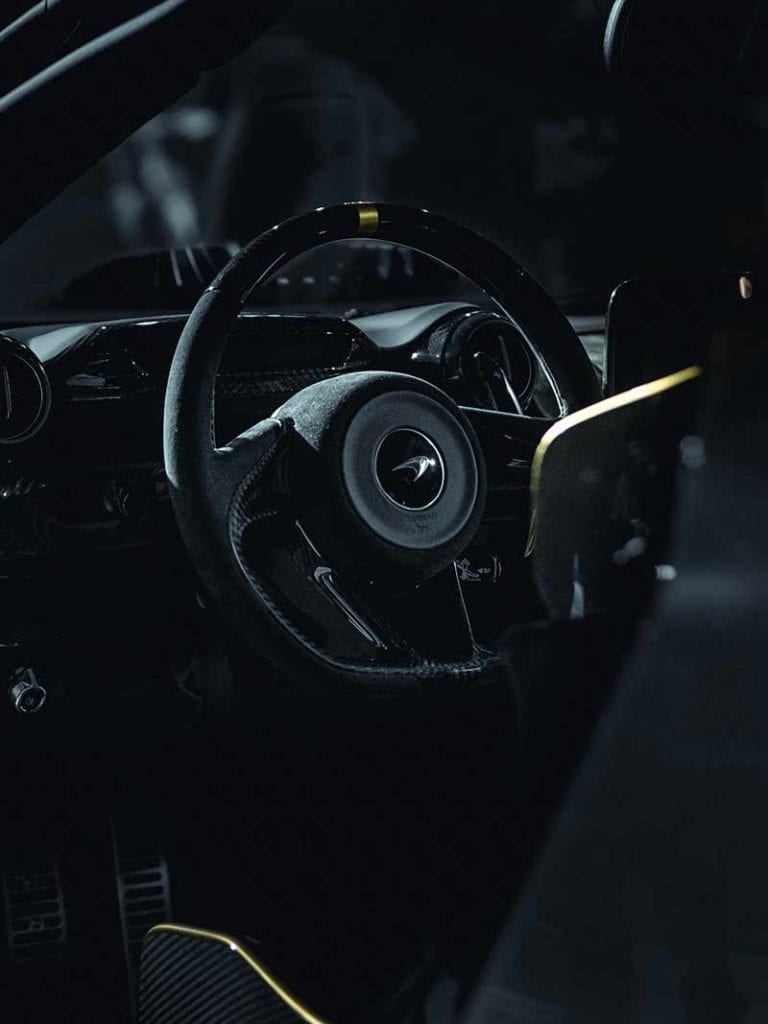

Automotive

Motorsport

Medical

Renewables

Technology

Marine

UK based, worldwide service

Offering design & engineering for global businesses

Piran Advanced Composites, based in the UK, serves as a Tier 1 supplier to major global OEMs. Our UK manufacturing sites enable us to deliver our world-class composite solutions internationally, ensuring that clients worldwide can benefit from our expertise and exceptional services.

Download our brochure

Design & engineering FAQs

What is composite Tooling?

Composite tooling refers to the specialised molds, patterns, and other tooling equipment used in the manufacturing of composite materials, particularly in industries like aerospace, automotive, marine, and wind energy. Composite tooling is especially critical in the aerospace industry, where lightweight and strong components are essential for aircraft and spacecraft. It allows manufacturers to produce complex shapes and structures with high precision and repeatability.

What are Composite tools made of?

Composite tools can be made from materials like composite materials, metals (aluminum, steel, Invar), epoxy tooling boards, RenShape and polyurethane tooling boards, fibre-reinforced plastics (FRP), or casting materials (silicone, epoxy). The choice depends on factors like temperature requirements and precision.

How does Piran control data and documents in regards to design?

We use an industry-leading PDM system, to facilitate efficient document control and management throughout the product development lifecycle.

What design format does Piran accept?

At Piran we can read in any CAD Design format.

What materials are used in Composites?

Composite materials typically consist of two main components:

1.Matrix Material (e.g., polymers, resins, ceramics).

2. Reinforcement Material (e.g., fibres like carbon, glass, aramid).

What is the average lead time on Design & Engineering services?

Lead time is product and industry specific. Get in touch so we can offer an estimate lead time for your project.

Does Piran Advanced composites guarantee quality?

Yes. We are NQA UKAS ISO9001 accredited and have a global reputation for impeccable quality.

Can Piran Advanced Composites provide Design & Engineering at scale?

Yes, we are proud to offer volume production at scale.